The decision is not about whether AI infrastructure is necessary. According to Gartner, global AI infrastructure spending will reach $280 billion in 2026. The question is which deployment path matches your timeline, risk tolerance, and operational capabilities.

This analysis compares three deployment models using objective criteria: deployment timeline, capital requirements, operational complexity, risk profiles, and total cost of ownership. The goal is decision support, not advocacy. Each model serves different organizational needs.

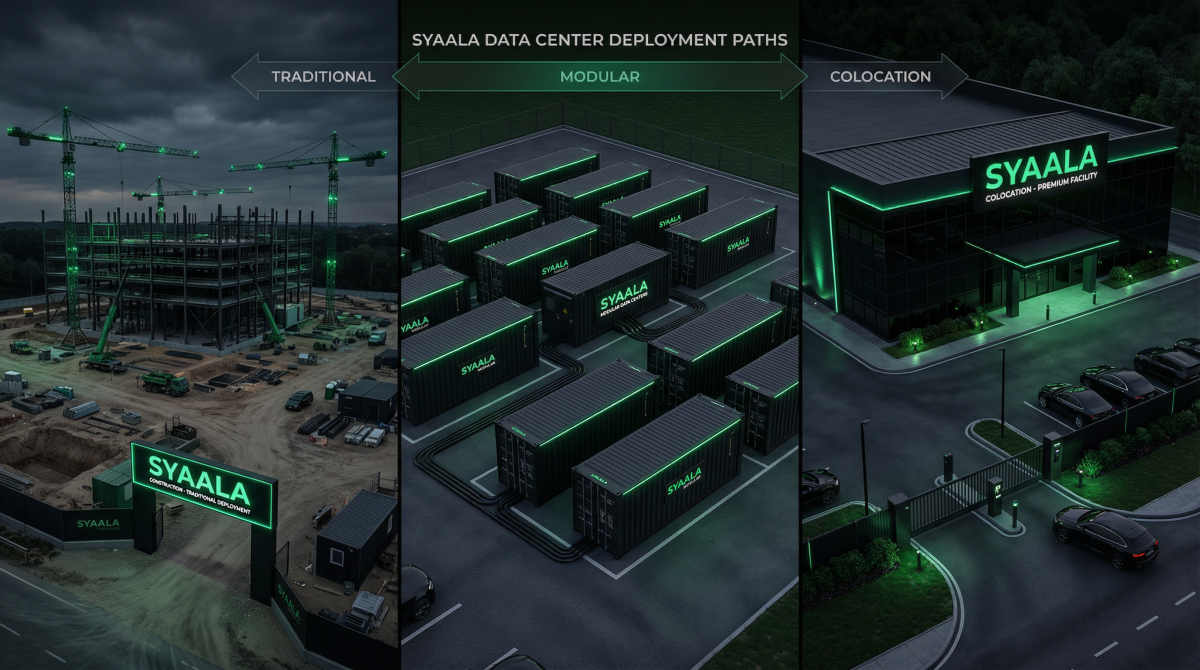

The Three Deployment Models

Traditional Data Center Build

Timeline

18-24 months

From site selection to operational

CapEx Range

$8-12M/MW

Plus land acquisition

Operational Model

Full ownership

Complete management responsibility

Traditional builds involve site acquisition and permitting (3-6 months), facility construction (12-18 months), equipment procurement with 12-18 month lead times, and testing and commissioning (2-4 months).

The Uptime Institute’s 2025 Global Data Center Survey found that 73% of traditional builds exceed their original timeline by 6+ months. Research on megaprojects shows 98% exceed budgets, with average overruns of 80% above original estimates.

Modular Container Deployment

Timeline

60-90 days

From order to operational

Cost Advantage

30-40% lower

Total cost of ownership

Operational Model

Owned infrastructure

Internal or MSP managed

Modular deployment involves configuration (1-2 weeks), factory manufacturing (4-6 weeks), site preparation concurrent with manufacturing, delivery and installation (1-2 weeks), and testing (1-2 weeks). Modules arrive factory-tested with integrated cooling, power distribution, monitoring, and fire suppression.

Enterprise Colocation

Timeline

72 hours

to 30 days

OpEx Range

$180-250/kW

Per month, enterprise GPU hosting

Operational Model

Zero CapEx

Facility management included

Colocation shifts risk from customer to facility operator. The operator owns responsibility for power redundancy, cooling capacity, physical security, and environmental monitoring. Deployment requires contract negotiation, equipment shipping, rack installation (24-72 hours), and network provisioning.

Decision Matrix Framework

Timeline Comparison: Speed to Production

Traditional Build

- Site acquisition: 3-6 months

- Construction: 12-18 months

- Equipment lead times: 12-18 months

- Testing: 2-4 months

- Total: 18-24 months

Reality: Start January 2026 → Operational Q3-Q4 2027

Modular Containers

- Configuration: 1-2 weeks

- Manufacturing: 4-6 weeks

- Site prep: 2-4 weeks

- Installation: 1-2 weeks

- Total: 60-90 days

Reality: Order January 2026 → Operational March-April 2026

Colocation

- Contract execution: Varies

- Equipment shipping: Customer

- Installation: 24-72 hours

- Custom configs: Additional

- Total: 72h-30 days

Reality: Available capacity → Deploy within one week

Total Cost of Ownership Analysis

3-Year TCO: 2 MW GPU Deployment

Scenario: Deploy 2 MW of GPU capacity in Q1 2026, operate for 3 years at 80% utilization. Power cost: $0.10/kWh.

| Cost Component | Traditional | Modular | Colocation |

|---|---|---|---|

| Initial CapEx | $21M | $12.8M | $8.15M |

| Cost overruns | +$16M | $0 | $0 |

| Operational costs (3yr) | $11.2M | $8.9M | $14.4M |

| Opportunity cost | $28.8M | $0 | $0 |

| Financing costs | $3.3M | $0 | $0 |

| Total 3-Year TCO | $80.3M | $21.7M | $22.55M |

TCO Savings vs Traditional Build

Modular Containers

$58.6M saved

73% cost reduction over 3 years

Colocation

$57.75M saved

72% cost reduction over 3 years

Risk Profiles: What Can Go Wrong

Traditional Build

High construction and execution risk

- → 73% exceed timeline by 6+ months

- → 98% exceed budget by 80% average

- → Contractor, labor, supply chain risk

- → Technology obsolescence during build

Modular Containers

Low construction risk, medium operational

- → Fixed pricing, predictable timeline

- → Site prep and installation risk remains

- → Requires operational capability

- → Factory testing reduces commissioning risk

Colocation

Lowest infrastructure risk, vendor dependency

- → Facility risk transferred to operator

- → SLA protection for uptime

- → Vendor dependency for capacity and access

- → Professional facilities management

Decision Framework: Use Case Mapping

When to Choose Each Model

Choose Traditional Build When:

- → You already own suitable land with utility capacity

- → Timeline is not urgent (24+ month planning horizon acceptable)

- → You require 10+ MW capacity at a single location

- → Your organization has deep facilities management expertise

- → Long-term (10+ year) commitment is certain

Choose Modular Containers When:

- → You need deployment in Q2-Q3 2026

- → Capacity requirements are 1-10 MW per site

- → You want owned infrastructure without construction risk

- → Regional distribution strategy with standardized deployments

- → You want flexibility to relocate infrastructure if needed

Choose Colocation When:

- → You need immediate capacity (within 30 days)

- → Your organization lacks facilities management expertise

- → You want to avoid CapEx and depreciation

- → Geographic presence needed in multiple markets quickly

- → Uncertain long-term capacity requirements

Conclusion: Matching Strategy to Context

The “best” infrastructure deployment model depends on organizational context, not abstract criteria.

Decision Criteria Summary

Timeline-Driven Decisions

Q2-Q3 2026 needs: Modular and colocation only. Traditional builds deliver in 2027-2028.

Cost-Driven Decisions

Modular offers lowest 3-year TCO for owned infrastructure. Colocation minimizes upfront capital. Traditional carries highest overrun risk.

Risk-Driven Decisions

Colocation transfers facility risk to operators. Modular reduces construction risk. Traditional carries maximum execution risk.

Capability-Driven Decisions

Organizations with deep facilities expertise can operate traditional or modular. Those without should default to colocation.

The 2026 infrastructure market favors speed and certainty over long-term cost optimization. Organizations that deploy operational capacity in Q2-Q3 2026 will capture market opportunity while competitors wait for traditional builds to complete in 2027-2028.

Evaluate based on your constraints: timeline, capital availability, risk tolerance, and internal capabilities. The decision matrix provides framework, but your specific context determines the optimal path.

Ready to Evaluate Your Deployment Options?

Use our infrastructure decision tools to compare deployment timelines, calculate total cost of ownership, and identify the optimal path for your organization.